- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

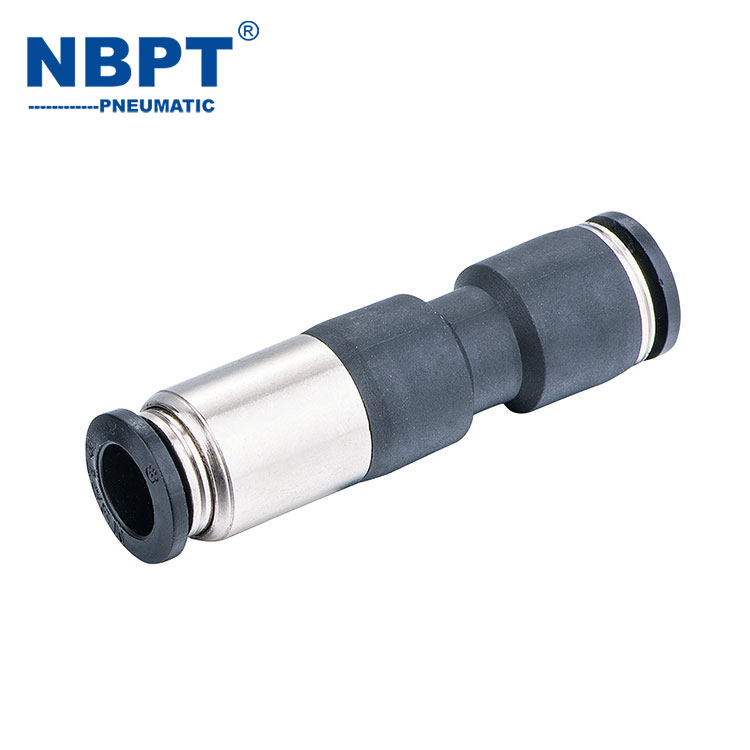

How can check valves achieve "zero leakage and reverse stop"?

2025-06-27

In the fields of industrial automation and energy management, excessive energy consumption of pneumatic systems has always been a pain point faced by enterprises. According to statistics, the energy consumption of compressed air systems accounts for 6% to 9% of the total industrial electricity consumption, and the energy waste caused by medium backflow is even more than twice as much, accounting for 15% to 20%. With the technological innovation of brass straight check valves, NBPT has optimized and achieved "zero leakage and reverse check", providing a core breakthrough for the industry.

Counter-flow leakage - The Invisible "black hole" of aerodynamic energy consumption

In pneumatic systems, reverse flow of the medium can cause frequent starts and stops of the compressor, fluctuations in pipeline pressure, and even lead to equipment damage. Due to problems such as seal failure and slow response, traditional check valves are difficult to completely block backflow, resulting in continuous energy loss. For instance, due to the leakage of a check valve, the annual pneumatic energy consumption of a certain chemical enterprise increased by over 300,000 yuan, and the equipment maintenance cost soared by 40%.

NBPT's four major technological breakthroughs achieve "zero leakage and reverse prevention"

In terms of materials, high-precision brass is selected as the dual guarantee of corrosion resistance and strength. The valve body is made of H62 environmentally friendly brass, which undergoes precision casting and heat treatment processes. Its hardness is increased by 20%, and the tensile strength exceeds 380MPa. This material remains stable in an environment ranging from -20℃ to 110℃. Its corrosion resistance is 50% higher than that of ordinary brass, effectively extending its service life and reducing the risk of leakage caused by material aging.

The structure adopts a straight-through flow channel design, balancing low resistance and high flow efficiency. The interior of the valve body uses a full-flow area straight-through flow channel, reducing head loss by 30% and making the medium flow more smoothly. This design avoids the accumulation of miscellaneous items and reduces losses. Measured data shows that under the same working conditions, the energy consumption of the pneumatic system of the NBPT check valve is reduced by 12% to 18% compared with traditional products. The valve disc and valve seat adopt a double-layer design of "soft seal + hard seal", which ensures low resistance when the medium flows in the forward direction and "zero leakage" when it flows in the reverse direction, completely blocking the backflow and becoming a solid guarantee for zero leakage

It is equipped with a high-elastic stainless steel spring to assist in rapid response, achieving almost millisecond-level reverse stop. When the medium pressure is lower than the set value, the valve disc closes quickly within 0.3 seconds, significantly improving the response speed compared to traditional products.

NBPT brass straight check valves are widely used in various industries, covering everything from energy to manufacturing. For example, natural gas pipelines, compressed air energy storage systems; Automated production lines, pneumatic tool pipelines Sewage treatment and waste gas emission systems. Its advantage of "zero leakage and reverse prevention" provides reliable guarantees for pneumatic systems in various industries, helping enterprises achieve energy conservation and consumption reduction goals.

Continuous innovation leads the new trend of energy conservation in pneumatic systems

NBPT will continue to focus on the pneumatic accessories field and plans to launch an intelligent monitoring brass direct check valve, integrating pressure sensors and Internet of Things technology to achieve real-time early warning and remote maintenance of backflow risks. Meanwhile, the company is developing a new generation of lightweight brass alloy to further reduce the weight of the valve body and enhance the efficiency of the pneumatic system.

Facing the challenge of pneumatic energy consumption, NBPT brass direct check valves, driven by technological innovation, share "zero leakage reverse check" with industry professionals. Welcome to contact us for more detailed information. In the future, NBPT will continue to be customer demand-oriented and promote the development of pneumatic systems towards greater efficiency and energy conservation.